Noise emitted by traffic causes disturbance both to biodiversity and people (see Chapter 1 – Ecological effects of infrastructure). Noise affects wildlife in different ways, such as behavioural changes due to difficulties with intraspecific communication and/or physiological stress, and noise can travel many kilometres from the infrastructure itself.

Different solutions are applied to mitigate the impact of noise, including placing the infrastructure between cuttings or earthen mounds, installing screens, using silent pavements or rail noise absorbers. Some of these measures have the additional benefit of reducing wildlife traffic mortality. However other impacts, such as barrier effects, may be increased and the choice of appropriate measures should be carefully evaluated.

Earthen linear mounds

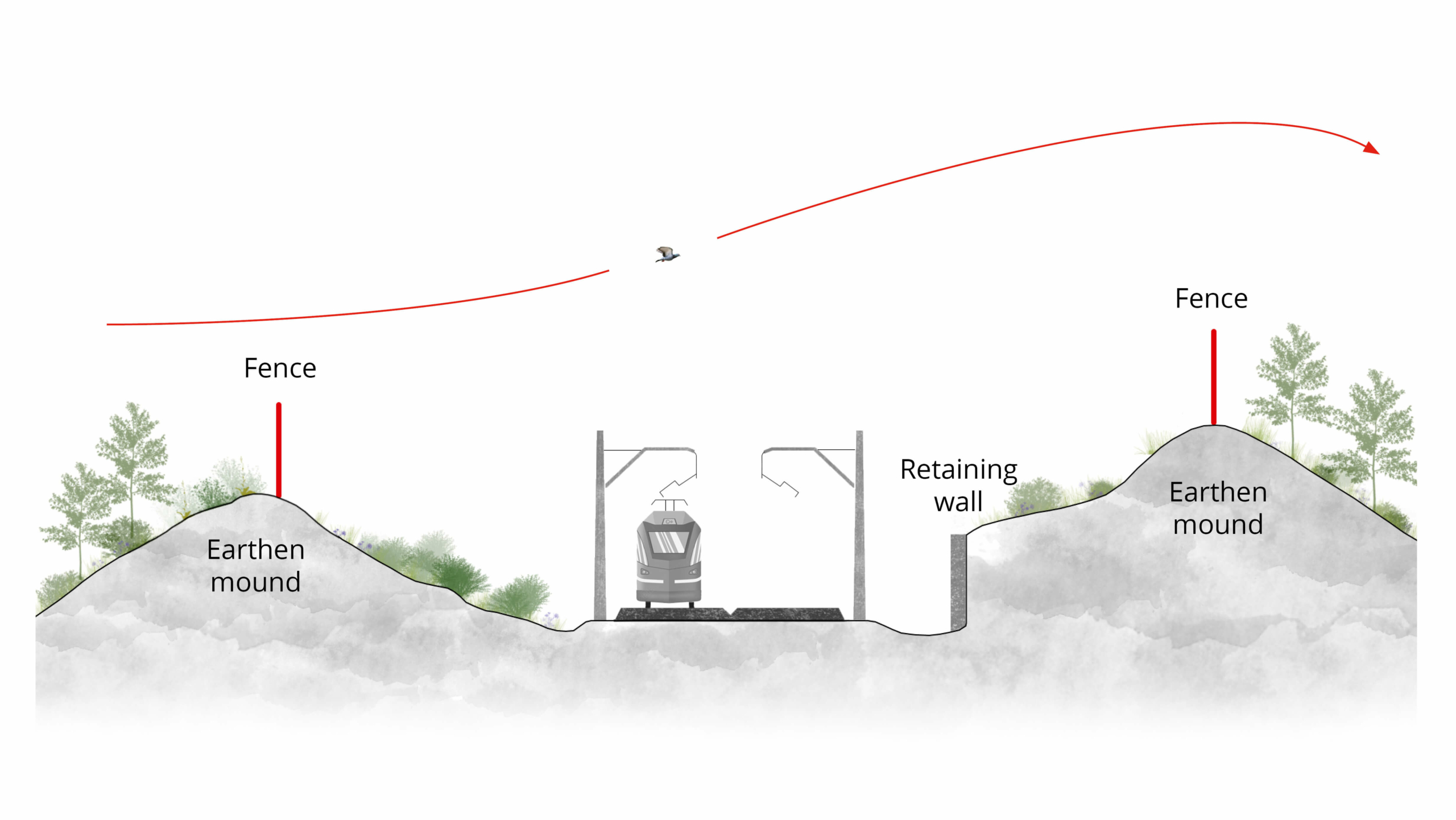

Roads and railways located between cuttings or linear earthen mounds allow traffic to be embedded in a corridor which reduces noise dispersal to adjacent areas.

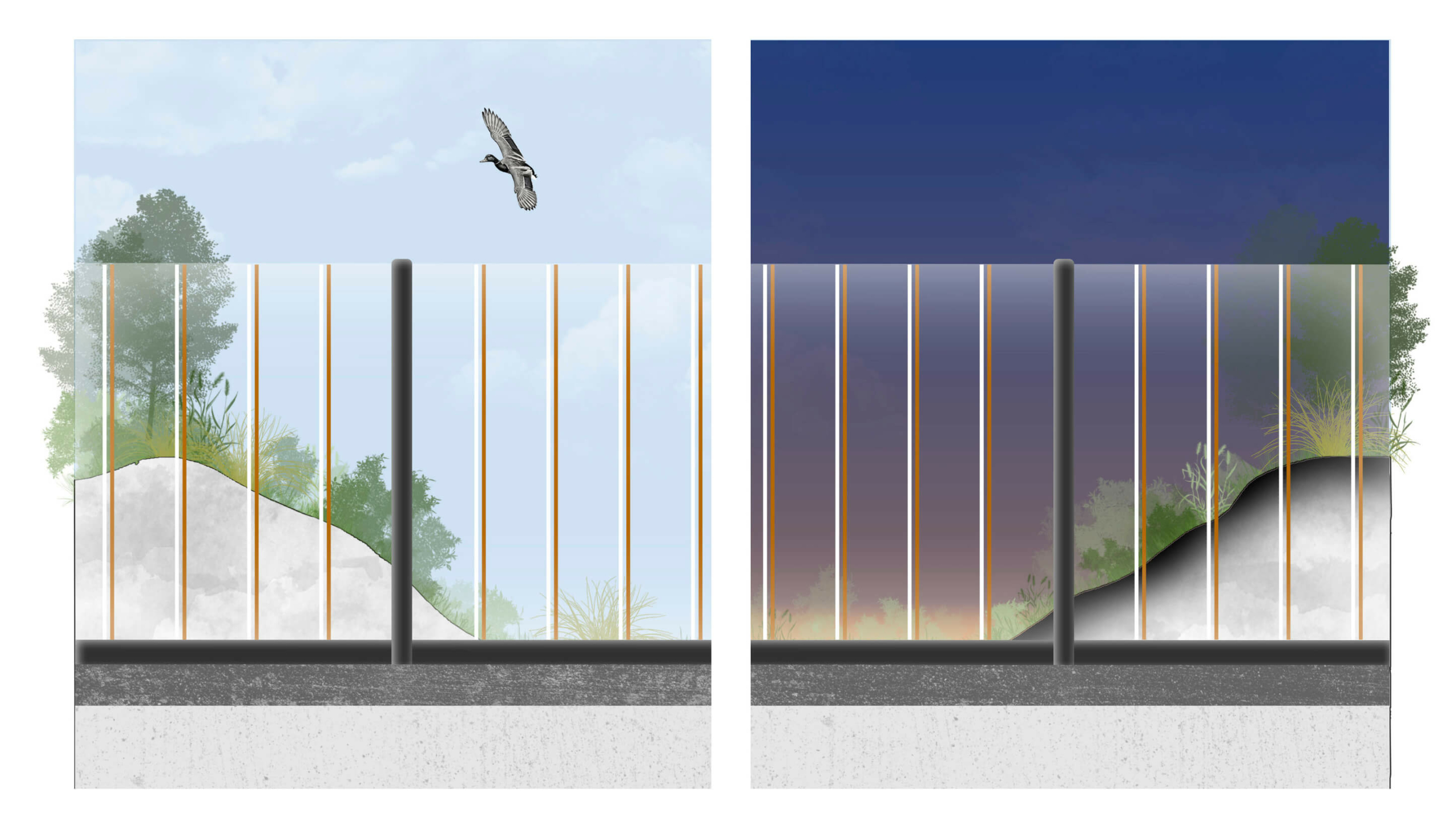

In flat areas, mounds of earth with appropriate vegetation cover can be constructed along road verges which reduce noise, provide visual screening of the infrastructure from the surroundings and have additional benefits such as reduction of risk of collisions with birds and other flying animals.

- Earthen mounds can only be constructed on wide verges of at least 12 to 15 m in width, but the width of mounds can be reduced by several metres using a retaining wall.

- When constructed in protected natural areas that require low noise levels, such as wetlands where large bird populations concentrate, earthen mounds can also prevent traffic collision with the birds in flight. To be effective, mounds should match the height of the tallest vehicles using the infrastructure. On railways, the minimum height of mounds should be at least 4 m to direct birds above the catenaries (see Section 5.7.2 – Verges and other green areas).

- If the verges are not wide enough, another solution is to combine earthen mounds with acoustic screens (Figure 5.6.5).

- Vegetation in these embankments must be carefully chosen and managed to avoid creating attractive habitats for nesting, feeding and perching, which could increase the risk of mortality for wildlife (see Section 5.7.2 – Verges and other green areas).

Noise screens

Screens are installed close to human settlements to reduce the impact of noise, although they can also be erected to protect biodiversity, e.g., colonies of breeding birds or river habitats, from disturbance.

- Screens built of concrete, wood or other material may reduce disturbance from noise and light, but can cause an increase in the barrier effect which may restrict movements of many species and isolate habitats from the surrounding landscape. Installation of screens in natural habitats must be carefully planned to balance the reduction of disturbance with the negative effects created by the barrier. In densely built-up areas, noise screens do not usually create any such problems.

- Combining noise screens in natural environments with wildlife passages reduces the barrier effect. In such cases screens should be designed to act as guiding structures towards the wildlife passages.

- Noise screens built of more substantial, solid materials may provide an opportunity to create artificial breeding structures for bats, birds or some pollinator species. These must be located on the side exterior to the infrastructure, except in the case of noise screens installed on both sides of ecoducts and other overpasses, where refuges must be installed in the interior part of the passage. In all cases it is important to ensure that an ecological trap is not being created by attracting animals to a hazardous area with high risk of collision with traffic.

Transparent screens

Transparent screens are used in areas where a view of the landscape is desirable for infrastructure users or to avoid issues such as shading which would be created by a non-transparent wall. These screens are often placed on bridges to allow drivers and passengers to see the surrounding landscape as they cross. Transparent screens may create a high mortality risk for birds which can easily collide with them. Hazards are increased where natural vegetation can be seen through the glass or bushes and trees are reflected. This also happens at windows of houses and higher buildings. It has been shown that by using appropriate markings, the number of collisions can be reduced substantially (Figure 5.6.6).

Design

- No reflective material or transparent glass should be used in new screens to be installed in sensitive areas with high risk of bird collision.

- To avoid bird mortality it is possible to cover transparent screens with materials that reduce the transparency or which apply a uniform colour to make the structure visible to birds.

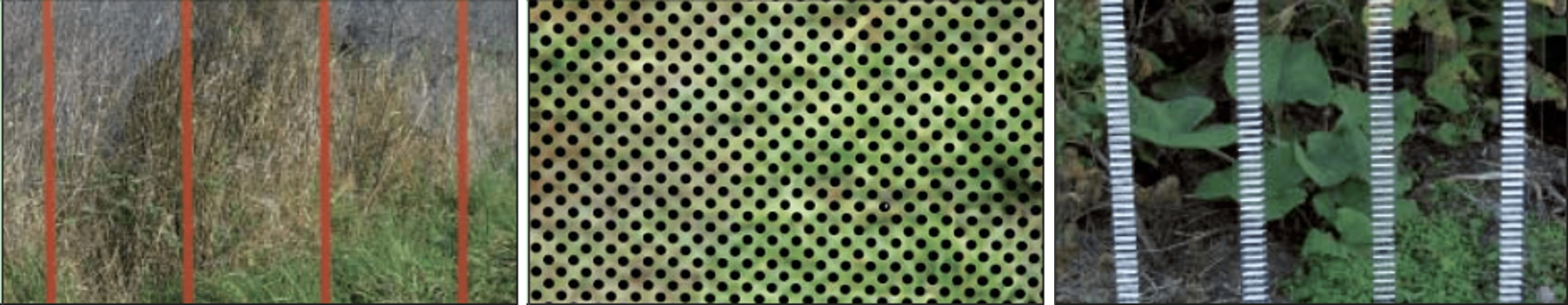

- Silk-screened strips or other patterns may be applied to screens. Vertical markings are recommended, although other pattern types may also be effective (Figure 5.6.6; Figure 5.6.7).

- Marking strips should be 2 cm wide with a distance between the strips of a maximum of 10 cm (or alternatively 1 cm wide, distance 5 cm).

- Light colours are preferable to dark because they are more visible at twilight. A combination of white and orange strips is a good solution visible in different light conditions (Figure 5.6.6).

- Markings should be applied on the outer side of the wall (i.e., away from road) to avoid reflection.

- If dot patterns are used instead of strips, dots must at least recover 25% of the screen surface.

- A complementary solution to reduce the mirror effect is the installation of materials with a reflectivity as low as 15%.

To be avoided:

- Silhouettes of birds of prey are not recommended. They are effective at preventing collisions only if put up at a very high density.

Points for special attention

- Wherever possible, transparent screens should be avoided. Non-transparent walls can be covered with bushes or climbing plants to make them visually acceptable.

- No trees or bushes should be planted in the vicinity of transparent noise barriers because this attracts birds and flying wildlife to the area and increases the risk of colliding with the screen. Where trees or bushes are planted as noise mitigation measures, transparent noise barriers should not be added.

Quiet pavements and low noise railways

Besides measures aiming to reduce the spread of noise to the surroundings there are also measures which aim to reduce the noise produced by traffic at its source.

Vehicle design is an important factor in noise produced by traffic, with engines and exhaust systems the primary sources. New electric motors produce much less noise than traditionally powered vehicles. Regarding the infrastructure, one of the most important sources of noise is produced by the contact between tyres of any vehicle and the road surface, which may produce noise between 500-2,000 Hz. The generation of this noise is influenced by tyre and pavement characteristics.

Quiet pavement materials could be applied to new and existing roads. Different types are being tested, such as porous or rubberized asphalt, with some properties to take into consideration:

- Texture. This is the most important characteristic of a road surface regarding noise mitigation. A reduction in the grain size of the asphalt reduces surface roughness and vibration, producing less noise. Although there are differences depending on the type of tyres, reduction in noise can be up to 4 dB between 8 mm grain versus 3 mm.

- Porosity. Most road surfaces have a porosity or percentage of volume consisting of air gaps of < 5%, but when porosity is ~ 20%, a 70-90% reduction in noise can be achieved. This is the principle of porous asphalt pavements.

- Stiffness. The difference between the stiffness of road and tyre generates impact forces that produce noise. One way of mitigating it is reducing the stiffness of the surface by adding other materials such as nylon fibres, recycled plastics and rubber crumbs. This is the principle of rubberized asphalt pavements.

Maximizing one of these parameters can be detrimental for others and reduce the effectiveness and durability of a road surface or increase the cost. For example, using a small asphalt grain size can correspondingly reduce the percentage of porosity. Current research aims to find the best combination of these characteristics for an economic and long-lasting solution.

In the case of railways, the source of the noise is heavily dependent on the train speed. At low speeds, the noise is mainly produced by the train’s power equipment while at medium or high speeds the rolling noise, produced by the contact between the wheels and the rails and the vibration this produces, becomes the most significant source. Aerodynamic noise is only a factor at very high speeds. Only rolling noise is considered here, since this source of noise can be influenced by the transport infrastructure features, such as the wheel and rail materials or the condition of the tracks. Some examples of measures aiming to reduce noise and vibrations are:

- Reducing roughness. Using smooth tracks can achieve a reduction of up to 10 dB, although to be completely effective, smooth wheels are needed. To achieve this, trains should be retrofitted with brake systems that do not cause wheel roughness. The effectiveness increases exponentially with the number of cars retrofitted in a railway, from 2.5 dB at 50% application to 8 dB at 100% of the train cars. Monitoring and maintenance of both tracks and wheels, for example grinding applied for quality and safety issues, can also contribute to reducing roughness and noise pollution.

- Installation of dampers or dynamic absorbers. These are devices that absorb vibration and convert it into heat energy. There are different types that can be installed in the wheels or rails, although most of them are composed of rubber materials.

- Rail shielding. This mitigation measure aims to avoid the spread of noise. It consists of steel panels partially enclosing the rail tracks and usually includes some damping materials on the inside.